Description

Liquid Form Enamels – Water Base

For spraying or dipping. Add water to thin if necessary. Can be mixed to create many colors. Ceramic pigments may be added to additionally create other colors. Will produce crackle effects when fired over low expansion enamels such as the crackle bases, 1006 White, 1020 White, 2008 Clear and 1997 Black.

Sold in dry form (4 oz, 8 oz, & 5 lb. jar); available in the drop down menu.

This product is available in dry powder. It contains a workable blend of glass, clay, and electrolytes. You need to add only water. Colors can be intermixed when in liquid form to create new shades of color.

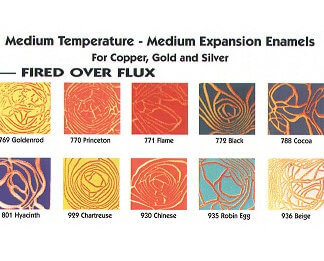

The product line includes: GC-16 (Cobalt Blue) Ground Coat for Enameling Iron (Opaque), BC-969A (Low Fusing Clear) Base Coat for Copper (Transparent), BC-303L (Medium Fusing Clear) Base Coat for Copper (Transparent), BC-1070 (Medium Fusing White) White Base Coat for Copper, 533 White (Highest Opacity White Opaque), (All Colors are Opaque) – 767 Peacock Blue, 769 Goldenrod Yellow, 770 Princeton Orange, 771 Flame Red, 772 Black, 774 Chocolate, 788 Cocoa Brown, 790 Imperial Blue, 791 Hunter Green, 799 Sky Blue , 800 Petal Pink, 801 Hyacinth Lavender, 929 Chartreuse, 930 Chinese Red, 935 Robin Egg Blue, 936 Beige, 937 Coral, & 940 Mouse.

Liquid Form Enamel was developed so that the enamel can be applied to a metal base by spraying, dipping, or pouring and in more recent times, applying with a brush. These application methods (except for brush application) were necessary in industry to mass produce enameled objects such as stove parts, washing machine tubs, pots & pans, etc. Liquid enamel’s formulation includes glass, clay & other mill additions which create a “set” in the liquid enamel after it has been applied & begins to dry.

Mixing Instructions for Dry Powder:

For small items a simple way to mix is to place a half teaspoon of powder into a plastic spoon. Using an eye dropper, add drops of water until the mixture is the consistency of ‘milk’. Apply to copper with a brush. Always make sure the powder and water have been stirred right before application as the glass falls out of suspension in the water very quickly.

For larger quantities, mix ¼ cup water to 5 oz. powder. To make a gallon of liquid, mix 14 lbs of powder to 2 quarts of water. The water to powder ratio may be adjusted up or down if needed for your particular project. If the liquid dries out, you can grind it back smooth in a mortar & pestle to re-constitute.

Tips for Using Liquid Form Enamels

1. Before application, always mix well as the glass quickly falls out of suspension in the water.

2. The water content is extremely important to the application firing result you get. Too little water & your result may look like cottage cheese. Too much water & the coating may fire dark with little color.

3. Colors can be intermixed when in liquid form to create new shades of color.

4. Left over liquid form enamel that dries out can be re-constituted & used again. Take dry material and place in a mortar & pestle to break down any dried clumps. Add water & use again.

Firing Instructions:

Make sure enamel product is completely dry before firing. For small pieces (less than 2” in diameter) fire at 1450 degrees F. for 1-1/2 to 2 minutes. For larger pieces (up to 6” diameter) fire at 1450 degrees F. for 2 to 3 minutes. For much larger work, firing times & temperatures should be determined for your specific project. Firing times and temperatures are meant as a guide only. You may need to adjust up or down for your own situation/equipment.

More information:

Expanded information on Liquid Form Enamel, spraying techniques & equipment, the crackle effect and more may be found in the Thompson Enamel Workbook (Cat. # TEP-001). Other enameling technical information may be found on Thompson’s website: thompsonenamel.com under ‘Enameling Help’.

* It should be noted that Thompson Enamel products are meant to be used for decoration purposes only. Thompson’s liquid enamel products are not meant to be used on food contact surfaces. Thompson Enamels are not formulated for impact or heat resistance.

Copyright Thompson Enamel 2019 All Rights Reserved

Reviews

There are no reviews yet.